Plant design and engineering data management solutions

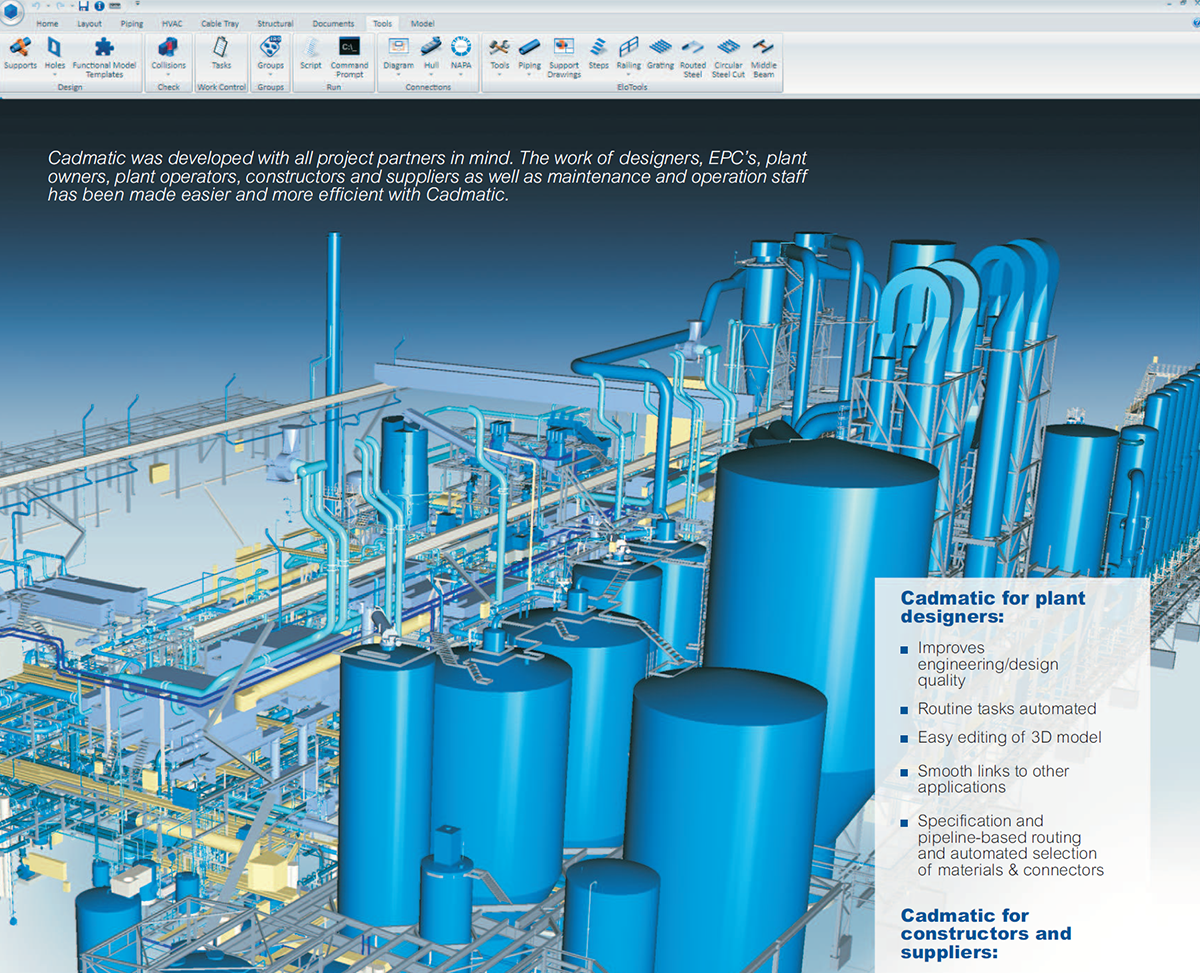

Cadmatic plant design and engineering data management solutions are used in a wide range of industries and for a wide range of projects. Our software development has always centered around creating software that suits the needs of plant designers, plant owners, plant operators/maintenance staff as well as constructors and suppliers. The versatile software is designed to make your work easier and more efficient.

Cadmatic for plant designers

Designers have amongst others appreciated the powerful and user-friendly design tools that improve engineering and design quality. Routine tasks are performed automatically and reliably with automated document production. The 3D models are easy to edit and are furthermore smoothly linked to other software applications, furthering Cadmatic’s scope of application.

An intelligent two-directional link between process diagrams and the 3D model means that changes are reliably updated. Specification-driven and pipeline-based routing as well as the automatic selection of materials and connector types are some of the features that ease engineering and allow engineers to concentrate on design rather than on laborious routine tasks.

Cadmatic for Plant Owners/Investors

The advanced design features of Cadmatic and its concurrent and distributed design capabilities result in shorter delivery times with reduced investment costs and design hours while at the same time ensuring higher quality design.

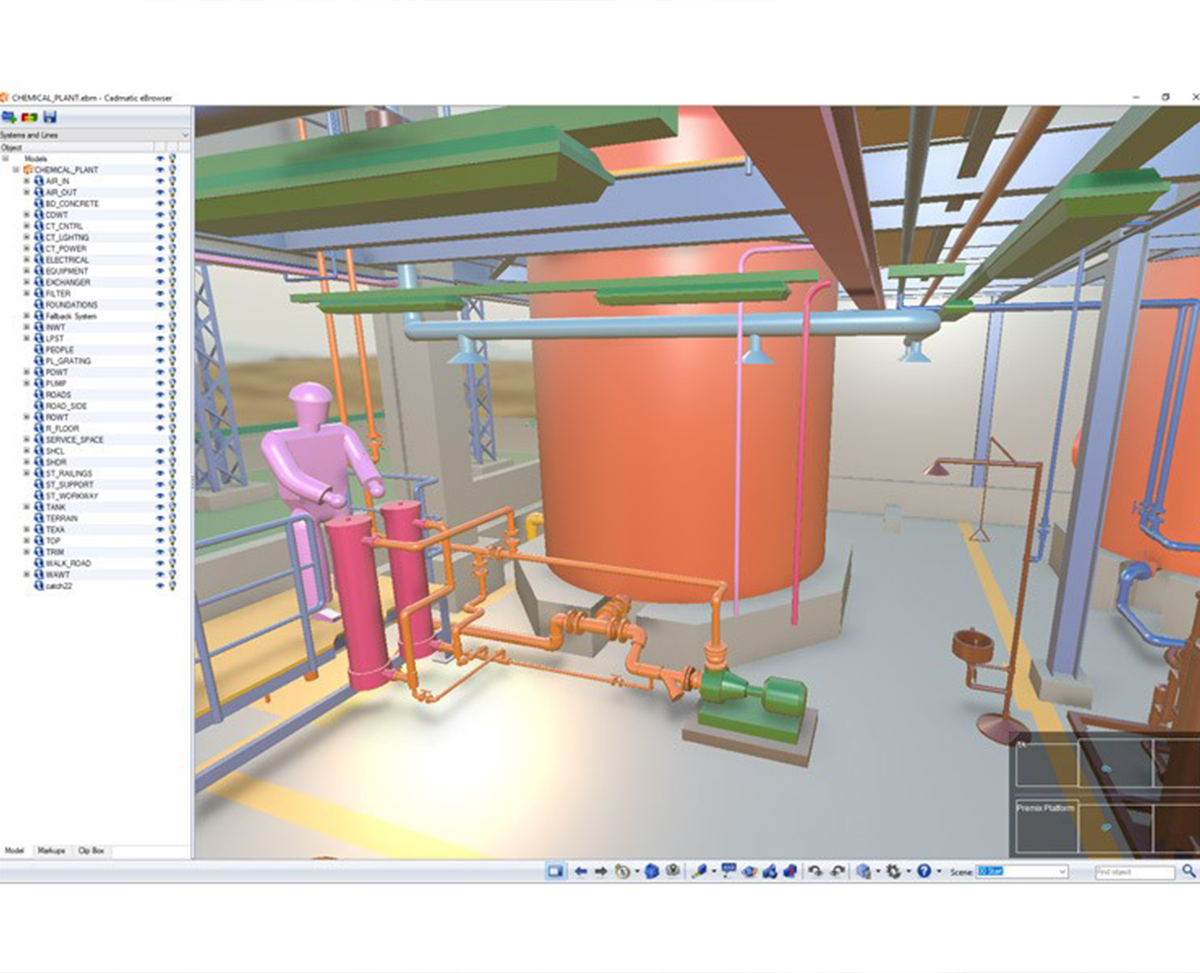

Owners and investors can use Cadmatic’s project review and communication tool, the eBrowser, to gain greater control over project developments. Plant visualizations and reviews are made easy and effective with access to the latest design information. Co-operation and communication between the owner and other project partners is greatly improved in this way. As Cadmatic is used throughout the entire life cycle of the plant investment the owner can effectively manage the whole process from pre-design to operation and maintenance with the help of eBrowser.

Cadmatic for operation and maintenance staff

Cadmatic can be used effectively during the commissioning and operational phases of the plant. Plant operators and maintenance staff can receive training with the 3D visualization tools even before the plant is completed. The engineering database and 3D model can be integrated with plant maintenance management system and thereafter the 3D model can be used as an information database and maintenance scheduler. Information can easily be updated in the model thereby replacing the tedious and inaccurate paper trails of former systems.

Cadmatic for suppliers and constructors

Cadmatic is designed for error-free production and the maximization of prefabrication. High quality production data such as digital information for numerically controlled workshop devices including cutters, bending machines and welding robots is produced. Suppliers and constructors receive accurate production information that can immediately be used for construction, prefabrication and installation. This cuts out time consuming errors leading to faster production and shorter building times.